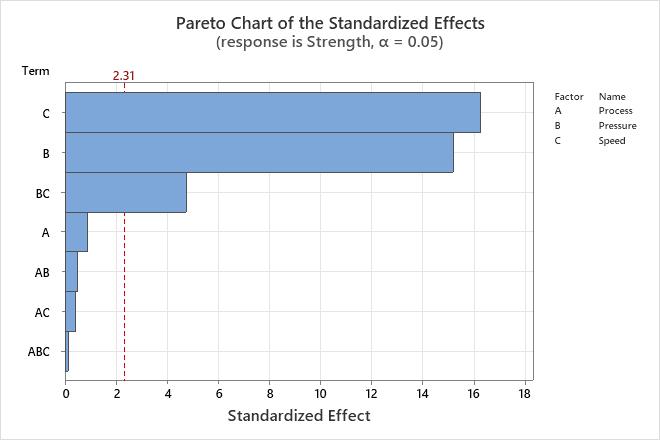

Many natural phenomena have been shown empirically to exhibit such a distribution. Use CaseĪs noted, Pareto Charts are not used solely for the purpose of quality control. However, this visualization can easily be applied to other events, such as business, where 80% of profits are regularly elicited from 20% of products. The most prevalent use case is for quality control, be it identifying the most common source of defects, the highest occurring type of defect, the most frequent reason for customer complaints, and so on. With a Pareto Chart, you are able to highlight the most important among a large set of factors. The Pareto Chart, derived from a histogram, views causes of a problem in order of severity from largest to smallest, ultimately demonstrating the Pareto principle. The principle was further developed, as Vilfredo observed that roughly 20% of the peapods in his garden contained 80% of the peas. This principle is named after Italian engineer, Vilfredo Pareto, who observed that 80% of the land in Italy was owned by 20% of the population. The chart is a derivative of the Pareto principle, which states that, for many events, roughly 80% of the effects come from 20% of the causes. Upon reaching the final bar, the line’s total will always be equal to 100%, representing the cumulative percentage share of all the bars (items).įigure 1 - Example of a Pareto Chart created in Dundas BI products) out of the entire group of items. For instance, the line begins at the top of the first bar, and as we move right, towards the second bar, the line displays the combined total of both bars as a percentage, representing the total share of these 2 items (i.e. A second and third level Pareto chart should be created to identify the root cause for defects among the team.The Pareto Chart is a unique visualization in that it contains both bars and a line graph, where individual values are represented in descending order by bars, and the cumulative total of those values is represented by the line from left to right. Now that the graph has been interpreted, the next step would be to continue analyzing the data to identify what is causing the effects in the 20%. The graph shows that just about 80% of the effects are coming from 20% of the causes. The connected data points above the bars represent cumulatively what each team is contributing as a percentage to the total number of defects. The percent under the count of defects shows what percentage of the total defects that team was accountable for. Team 4, with 25 of the 50 total defects, was placed on the left. The chart created by Minitab has sorted the teams in descending order by the number of defects create. In this example your effects are the defects and the causes are the teams. The purpose of running a Pareto analysis on this data set was to find how many defective products were being created by each team.

PARETO CHART MINITAB HOW TO

It’s important to know how to create a Pareto chart, but understanding what the chart is showing and being able to communicate that among team members is what makes this chart useful. The Pareto Chart will open in a new window.Select “Category” into the “Defects or attribute data in” box Select “Count” into the box “Frequency in.”.A new window with the title “Pareto Chart” pops up.Click on Stat → Quality Tools → Pareto Chart.

PARETO CHART MINITAB DOWNLOAD

0 kommentar(er)

0 kommentar(er)